Type S, N, and M Masonry Cement and Mortar - CEMEX USA

Type S, N, & M Masonry Cement + Mortar

Basic use of Masonry Cement

CEMEX’s Type N Masonry Cement, Type S Masonry Cement and Type M Masonry Cement are specially formulated and manufactured to produce masonry mortar. The masonry mortar is often used in brick, concrete block and stone masonry construction; it is also used to produce stone plaster.

Composition and materials

CEMEX’s Masonry Cement consists of a mixture of Portland or blended hydraulic cement and plasticizing materials (such as limestone, hydrated or hydraulic lime) together with other materials introduced to enhance one or more properties. These components are proportioned at the cement plant under controlled conditions to assure product consistency.

Types of Masonry Cement & Mortar

CEMEX’s Masonry Cements are produced in Type N Masonry Cement, Type S Masonry Cement and Type M Masonry Cement strength levels for use in preparation of ASTM Specification C-270 Type N, M or Type S Masonry Mortar, respectively without any further additions.

Table 1 is a general guide for selection of mortar type. Other factors, such as type and absorption of masonry unit, climate and exposure, applicable building codes, and engineering requirements should also be considered.

| TABLE 1 Recommended Guide for Selection of Mortar Type | |

|---|---|

| Building Segment | Mortar Type |

| Exterior, above grade, load-bearing non load-bearing parapet wall |

N or S or M N N or S |

| Exterior, at or below grade | S or M |

| Interior load-bearing non load-bearing |

N or S N |

Limitations

CEMEX’s Type N Masonry Cement, Type S Masonry Cement and Type M Masonry Cements are designed to be mixed with sand and water. The addition of hydrated lime or any other materials to a masonry cement mortar at the job site is not required or recommended.

Applicable Standards

The following standards are related to the use of CEMEX’s Portland Cements:

ASTM C-91 (Standard Specification for Masonry Cements)

ASTM C-144 (Standard Specification for Aggregates for Masonry Mortar)

ASTM C-270 (Standard Specification for Mortar)

ASTM C-780 (Standard Specification for Pre-construction and Construction Evaluation of Mortar for Plain and Reinforced Unit Masonry)

Water

All water should be clean and free from organic material and deleterious amounts of dissolved acids, alkalies and salts.

Physical properties

CEMEX’s Type N Masonry Cement, Type S Masonry Cement and Type M Masonry Cement conforms to physical properties of ASTM C-91 (See Table 2).

| TABLE 2 Physical Properties of Masonry Cements (ASTM C-91) | |||

|---|---|---|---|

| Masonry Cement Type | N | S | M |

| Fineness, residue on a 45-um (No. 325) sieve max., 35% | 24 | 24 | 24 |

| Autoloclave expansion max., % | 1.0 | 1.0 | 1.0 |

| Time of setting Initial set, min., hr. Final set, min., hr. |

2 24 |

1-1/2 24 |

1-1/2 24 |

| Compressive strength (avg. of 3 cubes), min. 7 days, psi (MPa) 28 days, psi (MPa) |

500 (3.4) 900 (6.2) |

1300 (9.0) 2100 (14.5) |

1800 (12.4) 2900 (20.0) |

| Air content, volume % Min. Max. |

8 21 |

8 19 |

8 19 |

| Water retention, flow after suction as % of original flox, min. | 70 | 70 | 70 |

Durability

Properties of masonry mortar related to its durability include:

- Resistance to freeze-thaw deterioration. Research[1][2][3] shows that air-entrainment levels of at least 10 to 12 percent are needed to provide effective resistance to freeze-thaw deterioration.

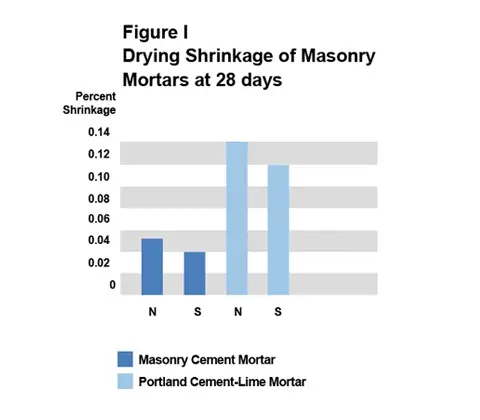

- Drying shrinkage characteristics. Results of laboratory test shown in Figure I indicate that the drying shrinkage of Masonry Cement Mortars is about half that of Portland Cement-Lime Mortars (See Figure I).

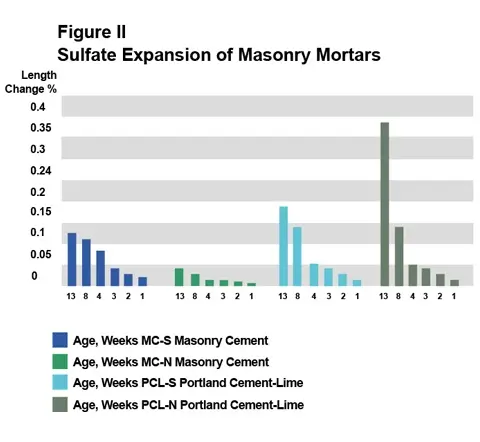

- Resistance to sulfate attack. Masonry Cement Mortars also demonstrate significantly greater sulfate resistance than Portland Cement-Lime Mortars (See Figure II).

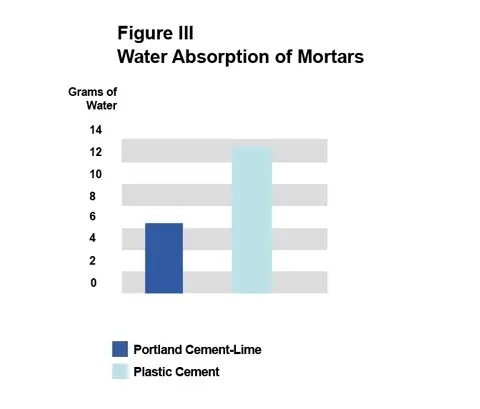

- Water permeance. The properties of Masonry Cement Mortars assure that the designer's and masons' needs are met in achieving watertight masonry construction. Laboratory research[4] has confirmed the excellent performance of Masonry Cement Mortars in water permeance tests (See Figure III).

Appearance

Since Masonry Cement color is laboratory controlled and Masonry Cement offers the simplicity of the one bag system of batching, it is easier to achieve consistent color cement for a prefect appearance in the finished job.

Installation

Preparation

CEMEX’s Type N Masonry Cement, Type S Masonry Cement and Type M Masonry Cement are proportioned with sand meeting ASTM C-144, according to Table 4, and will produce mortar meeting the requirements of ASTM C-270 under the proportion specifications. Under the property requirements of ASTM C-270, however, cement-to-sand proportions for the job mixed mortar are to be in the range of 1:2¼ to 1:3½, and the mortar must be pre-tested in the laboratory before the job begins.

Machine mixing should be used whenever possible. First, with mixer running, add most of the water and half the sand. Next, add the Masonry Cement and the rest of the sand. After one minute of continuous mixing, slowly add the rest of the water. Mixing should continue for at least three minutes; extending mixing up to five minutes improves mortar.

Application

Good workmanship principles are required for successful application, including proper filling of head and bed joints, careful placement of units, appropriate tooling of the joint, modification of construction procedures and/or schedules to adapt to extreme weather conditions[5][6] and proper cleaning procedures.

Masonry joints should be tooled at the same degree of stiffness and moisture. If joints are tooled too early, excess water will be drawn to the surface, producing lighter joints. The joints will appear dark and discolored if tooling is done after stiffening has started.

Hot Weather and Retempering

Mortars exposed to hot winds and full sun will tend to lose workability due to the evaporation of water. Common sense precautions should be taken to protect the mortar such as shading the mixer, wetting mortar boards, covering wheelbarrows and tubs, and balancing mortar production to meet demand.

If it is necessary to restore workability, mortar may be retempered by adding water and remixing. No mortar should be used or retempered beyond 2½ hours after the initial mixing.

Cold Water Precautions

Mortar should be maintained at a minimum temperature of 40° F as prescribed by standard cold weather masonry specifications. Cold weather admixtures should be approved by the architect.

Availability

CEMEX’s Portland Cements can be ordered by contacting at CEMEX Customer Care at:

Customer Care | 1-800-992-3639

Guarantees

CEMEX, Inc. guarantees Broco Stucco Cement when shipped from our mill or terminals to meet the current requirements of ASTM C-1328, “Standard Specification for Plastic (Stucco) Cement” and ASTM C-91, “Standard Specification for Masonry.”

Maintenance

Avoid use of harsh chemical cleaners or strong acid solutions in cleaning masonry.

| TABLE 3 Physical Properties of Masonry Cement Mortars (ASTM C-270) | ||

|---|---|---|

| Mortar Type | Compressive Strength 2” Cubes at 28 Days min., psi (MPa) | Water Retention Minimum % |

| N | 750 (5.2) | 75 |

| S | 1800 (12.4) | 75 |

| M | 2500 (17.2) | 75 |

| TABLE 4 Masonry Cement Mortar - Proportions by Volume (ASTM C-270) | |||||

|---|---|---|---|---|---|

| Mortar Type | Portland Cement | Masonry N | Cement S | Type M | Sand |

| N | - | 1 | - | - | 2-1/4 - 3 |

| S | 1/2 | 1 | - | - | 3-3/8 - 41/2 |

| S | - | - | 1 | - | 2-1/4 - 3 |

| M | 1 | 1 | - | - | 4-1/2 - 6 |

| M | - | - | - | 1 | 21/4 - 3 |

Technical Services Personnel

CEMEX personnel are available to provide technical assistance by contacting Customer Care at: 1-800-992-3639

Warranty

CEMEX warrants that the products identified are in accordance with the appropriate current ASTM and Federal Specifications. No one is authorized to make any modifications or addition to this warranty. CEMEX makes no warranty or representation, either expressed or implied with respect to this product and disclaims any implied warranty of merchantability or fitness for a particular purpose.

As CEMEX has no control over the other ingredients mixed with this product or the final application, CEMEX does not and cannot warrant the finished work.

In no event shall CEMEX be liable for direct, indirect, special, incidental or consequential damages arising out of the use of this product, even if advised of the possibility of such damages. In no case shall CEMEX’s liability exceed the purchase price of this product.

1. Dubovoy, V.S., and Ribar, J.W., “Masonry Cement Mortars – A Laboratory Investigation”, Research and Development Bulletin RD0095, PCA Skokie, IL, 1990, 26pp.

2. Davison, J.I., “Effect of Air-Entrainment on Durability of Cement-Lime Mortars”, Durability of Building Materials, Elsevier Publishing Co., Amsterdam, 1981.

3. Zematis,W.L., “Factors Affecting Performance of Unit Masonry Mortar”, ACI Journal, Proc. Vol. 56, No. 6, American Concrete Institute, Detroit, MI 1959.

4. Ribar, J.W., “Water Permeance of Masonry, a Laboratory Study”, ASTM STP 778, ASTM 1982, pp 200-220.

5. "Cold Weather Construction" and "Hot Weather Construction", ACI 530.1/95, Section 1.8, pp. 5-12, ACI, 38800 Country Club Drive, Farmington Hills, MI 48331.

6. "Recommended Practices and Guide Specifications for Cold Weather Masonry Construction”, International Masonry All Weather Council.