Smart Silo | Cement supply Management Program - CEMEX USA

Smart Silo - Facilitate your Cement Supply Management

How it works

Go Smart - Partner with CEMEX

Smart Silo™ eliminates administration and takes the guess work out of cement supply and silo management.

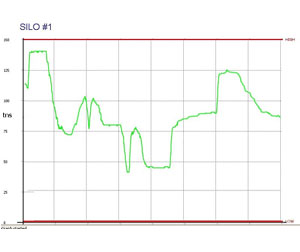

- CEMEX installs sensors in the customer's silos to track consumption and inventory information.

- The cement inventory levels are monitored and transmitted Online to CEMEX.

- CEMEX personnel use this information to create a demand plan.

- Cement is dispatched to the customer's site, ensuring a seamless and continuous supply.

- Customers can view current stock levels and orders received in the CEMEX Connect customer Online resource center.

Benefits

Automated service: CEMEX delivers your cement as needed. Customers can manage load information Online through CEMEX Connect.

Reduce administrative work: improves your plant's productivity by eliminating the hassles of order and inventory management.

Inventory control: Online visibility of your inventory consumption. Helps avoid stock-outs.

Perpetual vs. Physical inventory: assists in month-end reconciliation.

Equipment and installation is provided by CEMEX.

Getting Started

4 Easy steps to get Smart Silo™

The first step in the process of the Smart Silo™ installation starts with a site audit / risk assessment to make sure that your business is suitable for this innovative service.

A CEMEX representative will consider these main points in the site audit:

- Access and guidelines required for site survey

- Silos are assessed for suitability of retro-fitting Smart Silo™ equipment

- Ideally silos would be metal in construction and of stand-alone design, but we can accommodate other designs

- A broadband Internet connection at the site is required

- Suitable access around the silos is needed to effect a safe working environment when installing the equipment

- Service Level Agreement with terms and conditions and operational guidelines will be signed by CEMEX and our partners for enrollment

These are the main activities involved in the installation of Smart Silo™:

Installation

- Silos are prepared prior to fitting sensors

- Sensors are tested prior to installation

- Certified personnel will perform all electrical work as needed

- A broadband Internet connection at the site is required

- Installation is required in the batcher's cabin

- Smart Silo™ branding will be included in the installation

Calibration

The process of calibration is critical for Smart Silo™ operation requiring the silo to be emptied and refilled. CEMEX will coordinate the schedule with the customer.

The vessel has been filled and prepared through the calibration process. But before it goes live, control needs to be transferred to CEMEX.

The transfer of control process normally takes around 2 weeks.

Week 1 - Parallel operation of customer ordering and Smart Silo™ process.

Week 2 - Review results with customer and set operational guidelines to commence service.